Production

When the design of the display is approved the actual production will start. The die-cutting knives are made in our own die-cutting shop, the printing press will run, the cacher machine will make sure that the printed matter is glued to the cardboard and the die-cutting machine will eventually make sure that your display gets those beautiful contours. When all parts for the display are ready, it can be assembled.

Die cutting departement

In our die-cutting departement we make the die-cutting knives that ultimately determine the contours of your display. The making of the punching knives is still a very traditional craft because it involves a lot of handwork.

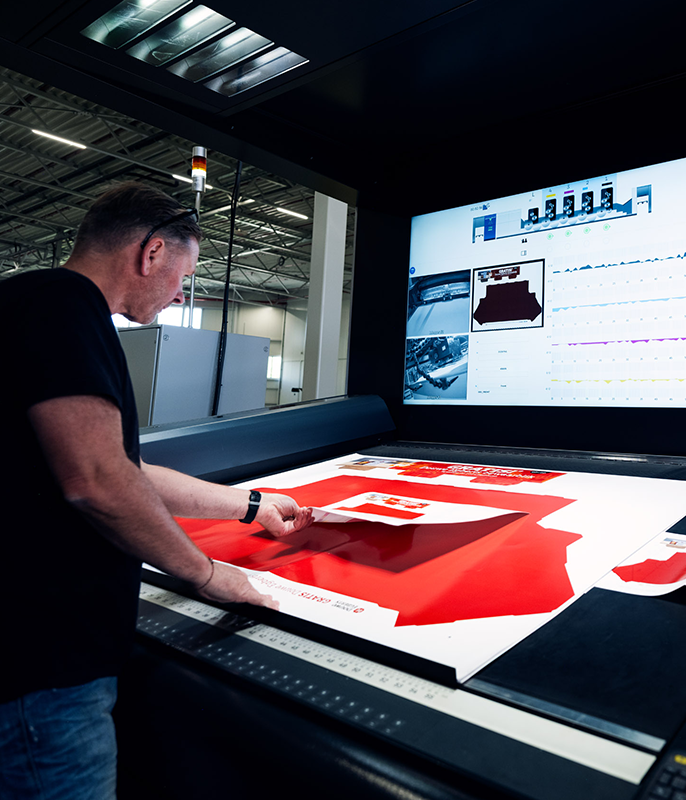

Printing

Our KBA Rapida 164 printing press produces 13,000 printing sheets per hour, measuring approximately 160 x 120 centimetres.

Laminating

By lamination we mean the gluing of printed matter on cardboard. Because direct printing on cardboard is not possible.

Diecutting

During cutting, the shape of the (parts) of the display is punched out of the cardboard.

Assembly

Now that all parts of the display are ready, everything can be assembled. This is done with the help of our Felix Robotgluers.